Kitchen Remodel: Episode 34 Where there was once a window, there is now a door! No I am trimming it, inside and out with the craftsman style that’s slowly spreading around the house.

Read MoreRipping Out a Window and Installing a Door

Kitchen Remodel: Episode 33 I’m tearing out an inefficient garden window in the kitchen and installing a new door in its place. We’ll have that secret coffee patio yet!

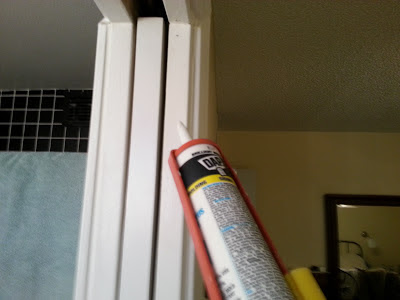

Read MorePatio Door Repair: The Threshold

A chain of failure lead from an anticipated quick fix to a complete replacement of the threshold for our patio French doors. Here’s how I fixed an old Jeld-Wen unit.

Read MoreMoving through another door

This time it was Jack's bedroom that got completed. His door had sat, half-painted for four months or so, while I tackled other pressing projects (see the index, April through July). I do get off-track.

I pulled his (young) man-cave door, complete with HAZ-MAT warning and an electrician's lockout tag-out tag out off it's hinges.

I've also started monkeying with the new DSLR camera and tripod, so "action shots" of yours truly are possible. Although, seeing my mug isn't much of an improvement, I can finally show some better photos than the ol' camera phone, and share some updates to my methods.

|

| Cooooooooookies!!! |

|

| Yes,.... that's the mighty, still not finished, organizer project under there. I'm not proud. |

Step 1: Slop some glue on toothpicks. Make sure to open the box in such a way that you spill them all over the floor as I have, otherwise the technique won't work. If you're wearing nice clothes to work in (ahem, Jeff), a damp paper towel is nice to have on hand.

Step 2: Jam a three or so gluey 'picks in the hole and savagely snap them off. There's no need for ceremony here. We're cleaning up after barbarians. Note: The spattered glue on my hands is a controlled exercise, just an educational illustration of one possible outcome, if you get overzealous in the glue application. It would never happen to me in real life. I'm sacrificing for you, dear reader.

Step 3: Run the screws in. Pro tip: I like to turn my screws in clockwise, otherwise known in the scientific circles as "righty-tighty". Do it your own direction, I'm just sharing what works for me. Again, I used the insulated #2 Phillips tip screwdriverbecause, well.... I don't know.

Review: Ryobi Door Latch Installation Kit

Reviewing the Rayobi Door Latch Installation Kit in action.

Read MoreFor the sake of updating,... and stuff

|

| Time to make the donuts... |

I have fiddled around with the site a bit, adding some favorite story links in the right margin for new visitors.

I've also launched a new side project. I thought I'd chronicle my adventures in learning photography. After a long saving's program, I've finally pulled the trigger and ordered a fancy new DSLR camera. Check out my little side project, AZ DIY Guy's Photography Adventures.

|

| http://azdiyguyphoto.blogspot.com/ |

Well it's off to Jury duty, a 15th wedding anniversary with my beautiful bride, and two Meet the Teacher nights this week,... plus, maybe a last coat of paint on this door? Have a great week my friends!

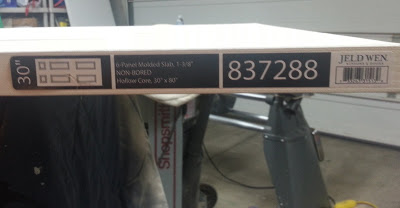

Review: JELD WEN Interior Doors (hollow core)

I'm well underway with replacing all the interior doors in our home. We started with flat slab, hollow-core doors that were probably original to the 1979 home. These originals are very plain, beat up, and so thickly coated with poor paintsmanship that there's no saving them. We've started replacing them one-by-one.

Some before and after action!

I've been picking up a hollow core, six panel doors from Home Depot by Jeld Wen. I believe Lowes sells the same brand, but I have my reasons to go to HD.

Concern?:

This sticker did not slow down the planer at all! It got chewed to bits.

I'm using the hollow core doors, because:

The originals were just fine, still structurally stable after 30+ years. It's a family home, not a great wall, fortified to withstand an onslaught of marauding Mongol hordes.

They cost $30.00 each. This is a serious improvement for a great price. I'm spending more on hardware than on the door.

Seriously, they're $30! (Compare to this investment, for more than $30)

I can man-handle these myself. They're light enough to prepare and hang solo, without having to lure a neighbor over with a craft-brew to get help wrestling a solid-oak, back-breaking beast onto the hinges.

They come off-white primed on six sides and have an embossed wood grain pattern. Painted a nice glossy white, even by hand, (...even with a 5 year olds assistance) they really finish up nice.

Of course, I had to plane mine down to size. I got a look at the construction, beneath the primer. The sides are a finger jointed, natural wood. It looks like pine. It's clean and free of knots and imperfections. The top and bottom are particle board. I'd prefer better, but it seems to work. Our old doors were the same. I just make sure I seal them up with primer and a couple coats of paint.

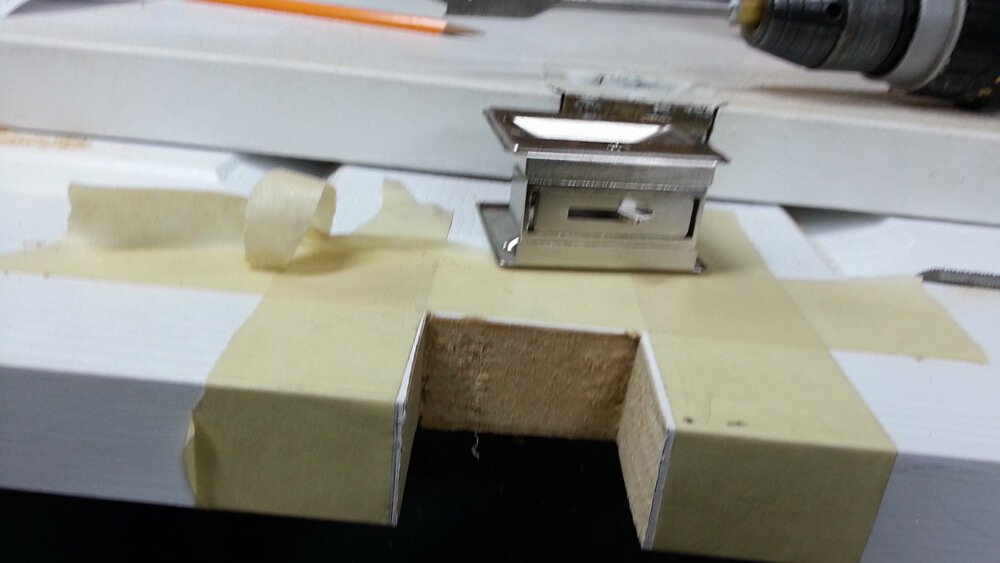

Clamping a sacrificial edge to prevent snipe and blow-out with the planer.

Because the standard sizes were too big for my framing, I bought them as slabs, no hinge mortises or holes for latches and knobs. They did have pre-bored in stock for a few bucks more, for those with houses not built by guys with short tape measures. I cut into mine for two different latch applications, there was plenty of meat left.

Surgery, to install a pocket door latch

The instructions limit how much you can plane down, 1/8" max per side. That was just fine for my application. I did it with a handheld power planer (Bosch).

Overall the quality was really good (see #'s 2&3 above!!!). So far, I only had one with a front that was coming off. It may have caught and popped up when they loaded it onto the shelf at the store. I glued and clamped it overnight before planing it down to size. Fixed!

I'm happy with this good-looking, easy-to-install Jeld Wen product. I have no problem recommending it to mid-skilled DIY'ers, with the proper tools, providing they don't require interior doors capable of stopping bullets.

If you'd like to follow my bumbling, door replacement adventures from the start:

Planning and decisions - Looking at doors, tools, and hardware (while sick as a dog)

Prepping a replacement pocket door - The inaugural first door

Installing a replacement pocket door - Saved the hardest for first

Prepping a replacement hinged door - Improving prep and shopping for hardware.

Installing a replacement hinged door - Here's my first hinged door install, including the first attempt at hinge mortising.

Review: Ryobi Door Hinge Template - Now I have it figured out!

Father & son DIY skills training - including the pitfalls of door shopping with your guard down.

I’m keeping this old, small version of the top pic on my site for a while. There is a carpentry business that stole my image and is passing it off as their own on their corporate website. Weird, right? - John

Father to Son DIY skills training

The two of us left the ladies behind and took a Friday night, before-bed trip down to grab door #4 for our interior door replacement project, this one for Jack's own room. He examined a couple from the top of the stack for dents and scratches before choosing a nice specimen from the middle of the stack.

|

| Get that doggie rollin' |

|

| You're going to have to sit this one out boy. Watch the master at work. |

|

Review: Ryobi Door Hinge Template

|

To those who haven't heard the term, a mortise is a recessed area on a door where the thickness of a hinge leaf is set, in order to lie flush with the surface of the door.

We've been slowly replacing all our ugly interior slab doors with nice looking six-panel beauties. After the initial pocket door experience and the guest bath door install, I'm getting the hang of it.

Without prior research, (very, very unlike me) I picked up the Ryobi Door Hinge Template

First off it's plastic. But it's that pretty tough stuff, not brittle. I also liked that all the parts (except drill bit and double end driver bit) fit neatly for on board storage. The kit includes instructions, corner inserts (reversible for 5/8" or 1/4" radius hinges), a guide rail for smaller / laminate routers, a router bit with top pilot-bearing, a 1/8" drill bit, a double-ended driver bit and the hinge mortiser unit itself.

|

| Yep, I'm wearing shorts and sandals. It's 85º today! (Sorry Detroit @ 27º) |

|

| Depth Charge! |

The instructions are pretty no-nonsense, bullet points. After setting the depth, they simply state:

- Turn on power tool and remove wood from template area

|

| Flat bottomed: It makes the rockin' world go 'round. |

A New Interior Door Adventure

I'm replacing all the old, flat panel hollow-core doors in the house with beautiful 6-panel doors. Here's how I installed the new door in the guest bathroom.

Read MoreInterior Door Project

Having successfully wrapped up the first of our interior door replacements last weekend with the

, I'm moving forward with the project. The rest of the doors are standard hinged style. The next one to tackle is the guest (

kids

) bathroom. It's one of the most visible in the house, we'll enjoy it being complete.

Pre-Primed, and too big

Rather than the more efficient, prefab / assembly line approach of buying all the doors, trimming all the doors, painting all the doors, etc. all at once, we're going with the slower, easier on the cash-flow approach of doing one door at a time. I suppose a benefit is that I don't have to stage doors all over the place as paint dries. Plus, we get to see some finished work a little sooner. The drawbacks are the repeated shop cleaning between each door's planing and painting as well as the wait time between paint coats.

I bought another six-panel door at Home Depot this morning. I also picked up a new brushed nickel, lever-style "door knob" (

What do you call it if it's not a "knob" anyway? The packaging doesn't even say

.) and a bulk pack of matching brushed nickel hinges. By buying the bulk pack of 12 hinges, I saved over ten bucks vs. buying them individually.

Buying in bulk!

Back at home, prepping this door was exactly the same as prepping the pocket door. Only this time I managed to screw up the edge planing of the first side. I sort-of tapered the door somehow; it was 1/16" off at one end. I must have twisted the depth knob when I was interrupted by a little girl offering to keep me company in the garage,... if I'd fix her a bowl of cookies 'n cream, ice cream. It took a bit of tweaking to get it squared up again.

I really like the Bosch planer . It took a bit of practice, but I have the hang of it now. The only struggle I have is the necessity to walk while cutting the long edge. Sometimes I get a little bobble in the cut. I ended up doing a shuffle / shimmy / slide / step-behind maneuver. It would probably be better to set the door on edge. I'll try that next time.

Grab your popcorn folks! Here's the world premier movie of AZ DIY Guy in action. I'm really much better looking in person, this particular role required a dusting of grey hair at the temple and an out of shape appearance. I think I pulled it off. It's certainly Oscar worthy.

There's a dust storm rolling in! Hold your breath and cover your eyes!

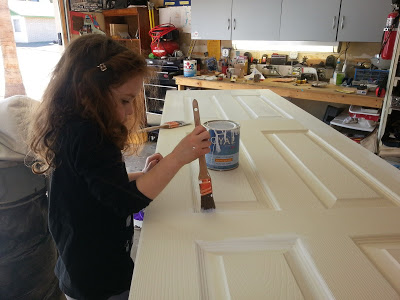

Gracie's been bugging me for a week to help with the painting, so I let her have a go of it. She did pretty good,... mostly. I had to keep reminding her not to scrub (destroy) the brush and tried to keep the splatter to a minimum. I lightly, quickly brushed over her work to keep the strokes with the wood grain. Despite the exuberant assistance, It turned out pretty well.

The paint dried fast in today's 78º, dry weather. I need to put one more coat on in the morning. Hopefully, I can get it done tomorrow.

<UPDATE>

Up before 6am Sunday morning, while the family slept, I put a coat of fresh paint on the reverse side of the door. I ran out of paint right at the finish line, dang-it. I scraped that can as clean as Gracie's bowl on a spaghetti night. I need to go grab some paint first thing and finish if there's any hope of installing it today.

Installing the New Pocket Door

I'm installing the new pocket door for the master bath today. I'd already prepared our new six-panel door, trimmed it to fit, primed the fresh edges, and painted the whole thing with a couple coats of white, semi-gloss last weekend. If you missed the story, find it here; it's a cliffhanger. The last coat of paint went on 6 days ago, so it's nice and dry, out in the workshop.

I'm installing the new pocket door for the master bath today. I'd already prepared our new six-panel door, trimmed it to fit, primed the fresh edges, and painted the whole thing with a couple coats of white, semi-gloss last weekend. If you missed the story, find it here; it's a cliffhanger. The last coat of paint went on 6 days ago, so it's nice and dry, out in the workshop.The dang thing keeps falling off its rail, plus it rubs on the inner walls of the pocket as it sways loosely from the track. I've already replaced the track mounting screws with larger screws, they seem to be holding. Look how ugly that beat up old slab door looks!

I pulled the top two trim pieces (casing?) off to access the mounting hardware, showering the whole area with bits of drywall from the rough edge behind. It isn't the best looking installation of trim I'd seen, with heavy globs of caulk filling the voids. Maybe when we redo the bathroom, I'll re-trim the whole thing with wide trim.

|

| Child Labor Rocks !!! |

|

| Like most men, I have a one-track mind. |

Turn the brain back on,.. climb back up the step stool,... crank the wheels back up,... climb down the step stool,... swing the door out,... climb back up the step stool,... extend the rollers again,...

|

| What do you think? Better? |

Prepping a replacement pocket door

I initially wanted to replace the track with a two rail type, where the wheels cannot easily disengage. However, based on my research, removing and replacing the track requires highly customized tools to get at screws deep in the pocket where you cannot reach, or opening the wall up. I'd rather not open the wall and get into a bunch of drywall repair and painting. I'm going to see if I can simply replace all the hardware and tighten up what I can get to. I'm replacing the beat-up, scratched, over-painted, bleeeechh slab door.

I picked up a 28" W x 80" H hollow core, six panel door at The Home Depot for $30 along with new hardware. Like all of our interior doors, the standard size was too big. I had bought a new tool, a handheld planer. I'd never used one, but I'd used a jointer, the same principle, just move the tool, not the work piece. I chose a Bosch 6 amp, 3 1/4 planer. (Maybe I'll review it after I've done all the doors in the house - so far, so good). It took a few passes to get the hang of it, but slowly felt comfortable taking deeper cutting passes.

|

| Notice my work bench? Yep, that's the (still) unfinished hall organizer project. |