I'm installing the new pocket door for the master bath today. I'd already prepared our new six-panel door, trimmed it to fit, primed the fresh edges, and painted the whole thing with a couple coats of white, semi-gloss last weekend. If you missed the story,

find it here; it's a cliffhanger. The last coat of paint went on 6 days ago, so it's nice and dry, out in the workshop.

The dang thing keeps falling off its rail, plus it rubs on the inner walls of the pocket as it sways loosely from the track. I've already replaced the track mounting screws with larger screws, they seem to be holding. Look how ugly that beat up old slab door looks!

I pulled the top two trim pieces (casing?) off to access the mounting hardware, showering the whole area with bits of drywall from the rough edge behind. It isn't the best looking installation of trim I'd seen, with heavy globs of caulk filling the voids. Maybe when we redo the bathroom, I'll re-trim the whole thing with wide trim.

There was a side piece of molding that kept me from swinging the door out from the bottom. First a quick score with the

utility knife to break the paint / caulk line:

I used a wide-blade

putty knife to slightly pry the molding out enough to stick my

mini-prybar/ nail puller behind it. Having learned from several past remodeling disasters, this time I took my time, gently wiggling the tools, then the molding itself as it slowly broke free. I want to reuse it when I reinstall the door. It actually came out in one piece!

If you look close, you can see the horrendous tile in the shower. Don't worry, it's on the to do list.

Jack stopped in and pulled all the nails that were left. The narrow head on the

mini-prybar/ nail puller made it easy without scuffing up the paint on the remaining trim. He had fun with it and did a great job.

There's another glimpse of that horrible black tile in the shower on the left.

|

| Child Labor Rocks !!! |

I learned why the door was swinging free, dragging on the pocket sides. There were plastic guides originally installed, but they were yellowed and brittle. They had snapped off sometime in the past 30 years. I also saw old water damage from our wonderful house flood a few years ago. (A toilet feed line had ruptured - I'll cover that in future story).

I needed another set of hands for the next step. Jack pushed the bottom of the door from inside the bathroom while I lifted the door up with the top of my foot from outside. The door pivoted from the track, hanging like a garage door. It took my mini pry bar and my favorite,

beefy, slotted screwdriver to pry the track and wheels apart. FREEDOM!!! The door popped out. I could see the wheels were well worn, compared to the replacements I have bought.

Looking inside the wall with a flashlight I can see I'm in luck. The track mounting screws inside the wall have not worked themselves loose, like the ones in the doorway had. I could only reach one with my screwdriver; it was tight, thank gods of remodeling. The whole plan to avoid cutting the drywall had hinged on this. Whew!

|

| Like most men, I have a one-track mind. |

In order to replace the broken plastic guide on the bathroom side of the door, I had to pry the inside molding up a bit. Unfortunately, I couldn't get it free. The floor tile had been installed after the trim piece and was encasing it. I tried out a tool I'd never used before, a "

Variable Speed Oscillating Multifunction Power Tool

". It plunge cut, flush with the floor, slicing the wood like butter. 30 seconds = done!

Mine is a Harbor Freight cheapie that I picked up a couple months ago on a whim; it was on sale. I'm sure it's not lasting quality, but it's a great concept. I'll definitely buy a nice, quality one whenever this one dies.

I pulled out the molding a bit, removed the old one that was installed with a finishing nail, and screwed the new one in. I'll adjust it later when the door is in.

I lugged the old door out to the workshop and laid it on top of the new one. Perfect match. With luck or possibly the benevolence of magical, midnight workshop elves visiting, I had managed to use the planer for the first time, to trim the new door down to a duplicate size without removing the old door.

It was interesting to note that the top, bottom, and pocket side edges were bare, unpainted wood. That's apparently a big no-no in humid environments. I didn't see any ill effects though.

Using the old door for placement, I matched the location of the roller hardware and installed the new ones by measuring, pre-drilling, and running the screws in tight with the

impact driver. The new hardware seems a lot heartier.

The big hex bolt adjusts the height of the rollers, more on that later.

I also copied the location of the latch from the old door. A very close call, I nearly cut the same size slot, but for some reason I read the instructions and learned that the new latch was 1/8" smaller. I shudder to think what foul words I would have befouled the neighborhood with if I had ruined the door by cutting an oversize hole. The old latch was painted and had a broken mechanism. My wife even cut her finger on it two days ago. I couldn't have used it.

I managed to scuff the new paint by dragging the old door's latch across the new one's face. To avoid more damage, I taped off the face of the new door, drilled a starter hole in the back of the slot and made three slow, steady cuts with the jig-saw. The new brushed-nickel latch fit perfectly.

Go time! I tipped the new door top first into the head of the opening and slipped the rollers easily into the track. Of course that is complete bull, a bald-faced lie.

I grunted and sweated that bastard into place crawling on my hands and knees back and forth, in and out of the bathroom trying to get those rollers to get into the track. For as many times as I had popped the old door back on track, I should have been able to do it with my eyes closed. AAAAAAAGHHHHH!!!

Finally, I turned my brain on for a second and adjusted the rollers so that the wheels were completely extended. It just took a few turns with a 1/2" wrench to extend them. Having only turned on my brain, "for a second" I was quick to realize that by cranking the wheels all the way up, it drove the door down, wedging it into the floor. I couldn't budge it. Idiot.

Turn the brain back on,.. climb back up the step stool,... crank the wheels back up,... climb down the step stool,... swing the door out,... climb back up the step stool,... extend the rollers again,...

This time, a quick prying motion with the mini-crowbar on the roller and the same with the screwdriver against the rail. Click-click, POW! Locked and loaded. I adjusted the rollers back up with the wrench making the leading edge square with the wall so there is no gap. The door slid closed smooth and easy. I installed the second guide at the bottom and tightened both. This door will not rub.

The original trim goes on with a quick "

skadoosh!" from the

finish nailer. It was easy to place since the original razor cut-line fit back together like a tight puzzle.

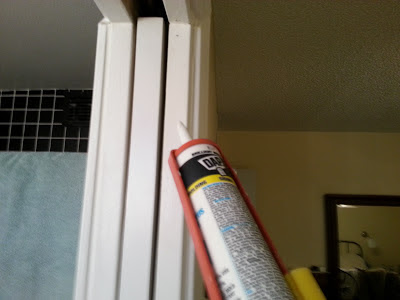

I've got it on the run now! Quickly swapping the nail gun for a caulking gun, I keep on shooting.

With wet caulk, I have to pause to address the more important task of enjoying a grilled cheese sandwich, a bag of Fritos, and a Diet Dr. Pepper that Sweetie whipped up for me. There's enough time to eat, clean up, and type up the story while it dries.

After a couple hours, I hit the trim and the door scuffs with a quick touchup of white paint. It's nice that I didn't have to remove trim from anywhere against wall color paint. It was all trim on trim / white on white, therefore no masking, just a quick layout of old newspaper on the floor to avoid drips.

Finished! I think it looks 100% better than before. It really dresses up the room a lot. The ladies will be pleased that the door finally, actually locks and won't fall off the track, trapping them in there.

Overall, it wasn't a super difficult project. It did take time to prep the door, but today's portion only took a couple hours to do.

|

| What do you think? Better? |

That's the only pocket door in the house. Next, I have six standard doors, the door to the garage, and a louvered closet door to replace.