Power Tool Storage

In cleaning up the garage after a couple weeks of heavy-duty weekend-warriorsmanship, I decided I'm not using my storage well enough. I'm having difficulty getting everything put away without heaping it up. There's two sets of double wall cabinets that I picked up on clearance about four years ago. They're cheap pressboard, but they're serviceable and seem to be holding up fine.

In cleaning up the garage after a couple weeks of heavy-duty weekend-warriorsmanship, I decided I'm not using my storage well enough. I'm having difficulty getting everything put away without heaping it up. There's two sets of double wall cabinets that I picked up on clearance about four years ago. They're cheap pressboard, but they're serviceable and seem to be holding up fine.I picked some choice specimens from the scrap pile and used the illustrious Kreg Jig Jr. to screw a sub-shelf together. (Honestly, I look for excuses to make Kreg Jig Projects) I made it shallower than the shelf-pin holes so I could hang the blade-guard of the circular saw below its edge and still get the door shut. It's a better use of vertical space.

|

| The routers are upside down to protect the bits that are set juuuuuuust right. |

The "Ted's Woodworking" Scam

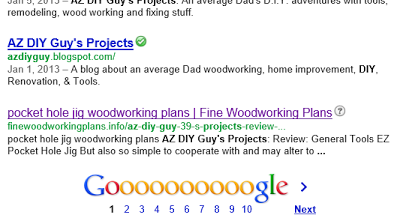

In the normal course of working on this blog, building readership, I did a search to see how it was showing up on Google. I searched some terms that were fairly unique, like "...too busy kicking old house ass..." before searching "AZ DIY Guy's Projects". I found this odd little link at the bottom of page one:

Fine Woodworking Plans?

Weird. It clearly referred to my General Tools EZ Pocket Hole Jig review post. Then the next phrase isn't mine. Huh? I thought I'd follow whoever shared my post and kindly ask them for a proper back-link. Here's where it went:

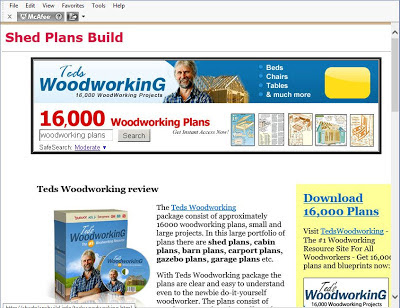

Huh? (Again). I kind of remember something about this from about a year ago. I checked around. Sure enough, this is the scam that Steve Ramsey of Woodworking for Mere Mortals posted several times about. Here's links to a few of the good ones: April 2, 2012, April 7, 2012, April 10, 2012.

Basically this site appears to be a shady affiliate in the Ted's Woodworking pyramid scheme of selling woodworking plans that have stolen from magazines and reputable sites around the web. There's tons of info out there on this huckster syndicate if you want to look for it, and can wade through all the paid advertising with fake reviews. I'm surprised they are still going, but these shadow scam things are hard to stamp out. I've researched a similar tactic from the Build Your Own Solar Panels for your Home scam in the past. It's all crap.

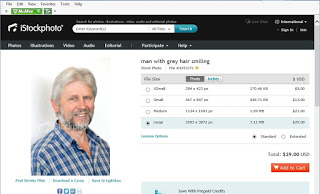

I even followed some comment links and found good old "Ted" AKA "man with gray hair smiling" at iStock Photo. Yep, good old "Ted" himself is a $29 image from a stock photo house.

Screen capture of iStock Photo

I wonder how the guy who sold his mug to a stock photo house feels about the way it is being used. The poor schlep is likely to be recognized on the street by an angry, wronged woodworker and get socked, unsuspecting in the jaw.

I'm not posting clickable links to this garbage. I don't want to give it any sort direct traffic. Here's where it gets me: how the heck did they embed my story title and text into a Google search?

I searched around a bit and, as near as I can tell, it's coming from paid, automated software that "legally steals" or "ethically steals" back link traffic. What the hell is that? Programmers create this stuff. People behind the sites sell and operate it. Bastards all.

Selling someone's plans without permission or plagiarizing their written word's in an effort to misdirect / or trick the web surfing public into a scam site that sells the stolen plans is stealing. It is unethical. Legal or not, if you take part in this, you are a scumbag, period. You are making money on the art created by the talents of others, without their permission, and from what I understand against their express statements denying permission.

So far, I've only been slightly wronged, maybe a tiny bit of misdirected traffic. I'm angry anyway. This site is barely two months old. Others are probably suffering actual damage. Plus, the artists that created plans that have been stolen have certainly been wronged. Please don't support it by buying this garbage. Do your research. Wait until you hear about the actual product you will receive.

OFFICIAL PROCLAMATION:

I hereby prohibit any of my created works, images, text or media of any kind from being utilized in any form to support the sale of Ted's Woodworking products.

Disclaimer:

This post is written with the research I was able to do on the web. I trust the sources I found, supporting my conclusion, as good and upstanding, and have no reason to doubt their claims. If I am wrong in my belief that the Ted's Woodworking Plans operation is a filthy, scamming, operation of thieving jack-ass-dom, I will remove this post and offer sincere apologies, without crossed fingers, once I see proof otherwise. I invite the scumbags to contact me, since they cannot be contacted directly to inquire.

Back to sunshine, rainbows, and happy projects next time, my friends. Promise.

The front door. Someone actually did this to their own home,... on purpose!

Undesired Inheritance from our DIY Predecessors

Remodeling a house and finding the half-assery left by previous, drunken DIY'ers.

Read MoreA New Interior Door Adventure

I'm replacing all the old, flat panel hollow-core doors in the house with beautiful 6-panel doors. Here's how I installed the new door in the guest bathroom.

Read MoreInterior Door Project

Having successfully wrapped up the first of our interior door replacements last weekend with the

, I'm moving forward with the project. The rest of the doors are standard hinged style. The next one to tackle is the guest (

kids

) bathroom. It's one of the most visible in the house, we'll enjoy it being complete.

Pre-Primed, and too big

Rather than the more efficient, prefab / assembly line approach of buying all the doors, trimming all the doors, painting all the doors, etc. all at once, we're going with the slower, easier on the cash-flow approach of doing one door at a time. I suppose a benefit is that I don't have to stage doors all over the place as paint dries. Plus, we get to see some finished work a little sooner. The drawbacks are the repeated shop cleaning between each door's planing and painting as well as the wait time between paint coats.

I bought another six-panel door at Home Depot this morning. I also picked up a new brushed nickel, lever-style "door knob" (

What do you call it if it's not a "knob" anyway? The packaging doesn't even say

.) and a bulk pack of matching brushed nickel hinges. By buying the bulk pack of 12 hinges, I saved over ten bucks vs. buying them individually.

Buying in bulk!

Back at home, prepping this door was exactly the same as prepping the pocket door. Only this time I managed to screw up the edge planing of the first side. I sort-of tapered the door somehow; it was 1/16" off at one end. I must have twisted the depth knob when I was interrupted by a little girl offering to keep me company in the garage,... if I'd fix her a bowl of cookies 'n cream, ice cream. It took a bit of tweaking to get it squared up again.

I really like the Bosch planer . It took a bit of practice, but I have the hang of it now. The only struggle I have is the necessity to walk while cutting the long edge. Sometimes I get a little bobble in the cut. I ended up doing a shuffle / shimmy / slide / step-behind maneuver. It would probably be better to set the door on edge. I'll try that next time.

Grab your popcorn folks! Here's the world premier movie of AZ DIY Guy in action. I'm really much better looking in person, this particular role required a dusting of grey hair at the temple and an out of shape appearance. I think I pulled it off. It's certainly Oscar worthy.

There's a dust storm rolling in! Hold your breath and cover your eyes!

Gracie's been bugging me for a week to help with the painting, so I let her have a go of it. She did pretty good,... mostly. I had to keep reminding her not to scrub (destroy) the brush and tried to keep the splatter to a minimum. I lightly, quickly brushed over her work to keep the strokes with the wood grain. Despite the exuberant assistance, It turned out pretty well.

The paint dried fast in today's 78º, dry weather. I need to put one more coat on in the morning. Hopefully, I can get it done tomorrow.

<UPDATE>

Up before 6am Sunday morning, while the family slept, I put a coat of fresh paint on the reverse side of the door. I ran out of paint right at the finish line, dang-it. I scraped that can as clean as Gracie's bowl on a spaghetti night. I need to go grab some paint first thing and finish if there's any hope of installing it today.

Installing the New Pocket Door

I'm installing the new pocket door for the master bath today. I'd already prepared our new six-panel door, trimmed it to fit, primed the fresh edges, and painted the whole thing with a couple coats of white, semi-gloss last weekend. If you missed the story, find it here; it's a cliffhanger. The last coat of paint went on 6 days ago, so it's nice and dry, out in the workshop.

I'm installing the new pocket door for the master bath today. I'd already prepared our new six-panel door, trimmed it to fit, primed the fresh edges, and painted the whole thing with a couple coats of white, semi-gloss last weekend. If you missed the story, find it here; it's a cliffhanger. The last coat of paint went on 6 days ago, so it's nice and dry, out in the workshop.The dang thing keeps falling off its rail, plus it rubs on the inner walls of the pocket as it sways loosely from the track. I've already replaced the track mounting screws with larger screws, they seem to be holding. Look how ugly that beat up old slab door looks!

I pulled the top two trim pieces (casing?) off to access the mounting hardware, showering the whole area with bits of drywall from the rough edge behind. It isn't the best looking installation of trim I'd seen, with heavy globs of caulk filling the voids. Maybe when we redo the bathroom, I'll re-trim the whole thing with wide trim.

|

| Child Labor Rocks !!! |

|

| Like most men, I have a one-track mind. |

Turn the brain back on,.. climb back up the step stool,... crank the wheels back up,... climb down the step stool,... swing the door out,... climb back up the step stool,... extend the rollers again,...

|

| What do you think? Better? |

Prepping a replacement pocket door

I initially wanted to replace the track with a two rail type, where the wheels cannot easily disengage. However, based on my research, removing and replacing the track requires highly customized tools to get at screws deep in the pocket where you cannot reach, or opening the wall up. I'd rather not open the wall and get into a bunch of drywall repair and painting. I'm going to see if I can simply replace all the hardware and tighten up what I can get to. I'm replacing the beat-up, scratched, over-painted, bleeeechh slab door.

I picked up a 28" W x 80" H hollow core, six panel door at The Home Depot for $30 along with new hardware. Like all of our interior doors, the standard size was too big. I had bought a new tool, a handheld planer. I'd never used one, but I'd used a jointer, the same principle, just move the tool, not the work piece. I chose a Bosch 6 amp, 3 1/4 planer. (Maybe I'll review it after I've done all the doors in the house - so far, so good). It took a few passes to get the hang of it, but slowly felt comfortable taking deeper cutting passes.

|

| Notice my work bench? Yep, that's the (still) unfinished hall organizer project. |