After finding a plumbing leak and tearing holes in the all, it's time to repair the pipes. Soldering and using handy push-fit connectors.

Read MoreSurprise! Finding a leak inside the wall.

I could hear something inside the wall. Note: This phenomenon, is generally what we like to call in the homeowner business, "bad news". Rarely, do noises in the walls turn out to be the shifting of gold doubloons sliding off a big bundle $20 bills onto a pile of 30 year old Apple Computer stock. No, it usually means you are going to spend money, lots of it. It is, however, a perfect opportunity to practice up on your curse words.

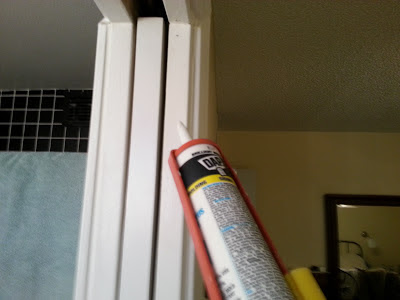

With the shower valve opening too small, I couldn't see into the wall, but I could hear water spraying. With the crud-circle buildup around the valve cover as a guide, I cut the hole larger with a rotary tool. The fumes and dust of cutting fiberglass were pretty strong, so I opened a window, turned on the exhaust fan, and slipped into the manly-pink 3M Professional Multi-Purpose Respirator

|

| "No Luke, I am your Father" - D. Vader |

|

| I don't see any hidden treasure either. |

|

| Fact: This age-old smartphone trick is believed to first been used in Boston, circa 1771.

- The More You Know

|

|

| The culprit. |

|

| Wasn't there a bending wall scene in Poltergeist? |

|

| This is not the work of a Sheetrock saw, just a simple pocketknife blade. |

|

| Can't you just see the joy on my face? |

|

| Cool mist. |

|

| At least it was a small bucket. |

|

| Sure it's a nice torch kit, but can you take your eyes off that delicious 1970's counter top? |

The Great Fix-It yourself Contest Winner!

A couple weeks ago I shared some of my DIY stories and asked about yours:

What have you done to save the family budget and keep stuff from the landfill? What's the one thing you're glad you fixed rather than throwing away? What fix it job are you most proud of?

Crucial Vacuum sponsored the contest for a $100 Amazon.com gift certificate.

Here are some of the great responses:

Jess:

"I'm not a mechanic or technician.....at all. And I'm uncomfortable with electricity so any fan or light fixture replacements are done by my dad or friends, so I can't take credit (except for skillfully selecting excellent amigos), but I have replaced my tub's faucet and I took off the drain to remove a hair-based clog in the tub. I figure I would have had a plumber come out for that, so probably saved me $100. And learning to do that was empowering enough that I put on some Spice Girls music to celebrate."

Eric:

"I bought my first Arizona tract home during the frenzy of 2005, so naturally I was broke the following year when the AC quit working. I spent some quality time in the attic replacing the fan motor and controller board and probably sweat off a few pounds in the process. The real feat in this whole experience was finding a place that would sell me the parts. Thankfully I found a small shop in Mesa that saved me from having to wait for parts to be shipped"

Margaret:

"I replaced the lid switch in the washer of our rental. It worked and the washer is still going strong several years later!"

John:

"I recently replaced the drain pump on our front loading washer. These things aren't really designed with ease of maintenance in mind. Got more scratches on my arms than if I got in a fight with a rabid bobcat." (Check out John's blog: Our Home from Scratch)

Brian:

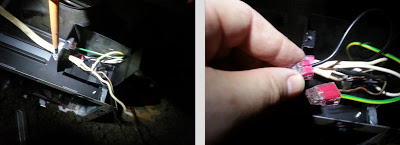

"I am always trying to save a dime. One day my grinder stopped working and I thought it was the power switch. I never fix a grinder before, and I could have bought another for 10 bucks at Harbor Freight. However, I thought that I would open it up and see if I could fix it myself to save some money. Worse case scenario if it was thrashed I would at least know I tried before I junked it. I opened up the case and one of the brushes a brass plate was off one of the brushes.

I could have stopped and bought a new set of brushes but these had a lot of life left in them so I figured I would find a way to fix it. All I had to do is solder the brass plate to the wire that is embedded in the brush head. Now in order to do this, I had to find a way to hold everything and compress the spring that goes over the wire, in between the brass plate and the brush head. Enclosed is some pictures of my solution."

Check out Brian on his site too! Summers Woodworking He has an infectious joy for woodworking and tools.

Ben:

"I fixed a broken soap holder in our tiled bathtub wall. We realized there was a problem when there was a leaking ceiling in the utility room that the tub sits over. The previous owners were the type that knew just enough about everything to screw it all up. Turns out there wasn't enough of a stud to screw the soap holder into, so they shoved a few pounds of drywall mud and shoved it in. Well, needless to say it started sagging from my two year old doing chin-ups on it (I exaggerate). I had to rig a 2x4 extension to the stud that was half visible and add a few tiny sheets of plywood to fill the gap of missing drywall, then I lathered it with liquid nails and taped it up for a few days and voila! No need for a plumber and saved countless dollars."

Thank you everyone for the stories. It is an impossible thing to pick the best. My friends a Crucial Vacuum picked the top two. I was frozen with indecision, so I had to flip a coin to make the final call.

Congratulations to John V who wins the $100 Amazon.com gift certificate!

Thank you to Crucial Vacuum for being the prize sponsor for this fun contest. Please check them out when you need some parts, supplies, and information for your DIY vacuum repairs.

www.criticalvaccum.com. Back to regularly scheduled programming soon friends!

The Great Fix-It Yourself Contest - $100 prize!

On this blog, I like share tales of "Fixing Stuff". Now, we want to hear yours.

One comment / story is going to earn a $100 bounty, a glorious Amazon.com gift card from our friends at Crucial Vacuum! (update: Contest over)

Over the years, I've taken advantage of the internet's easy accessibility to repair parts and educational resources to fix stuff that I would have either thrown away and replaced or paid someone the big bucks to repair for me. It's become my first reflex to tear stuff apart and fix it. I've saved tons of money in the process.

Replacing the cord on the dust collector.

Of course there's risk involved. I've attacked a repair, casually ignoring the "no user serviceable parts" label only to find that not only was I unable to fix the item, I couldn't even hope to put it back together. I am embarrassed to admit I did the walk of shame to the trash bin with an armful of plastic, electronics, tubes and dangling wires that had once been a beautiful Keurig Platinum coffee brewer.

We lost a $130 coffee brewer in that debacle, but it was busted and out of warranty anyway. I'm not going to do a brake repair job on my wife's car in the driveway, because I don't know what I'm doing. I'm not going to risk my family to save any amount of money. I leave that one to the pros.

I've had my successes as well. Here's a rundown of some of the highlights...

- Remember the dealership challenge? It saved almost $100 and it took only a few minutes of my time to replace the auxiliary audio jack in my truck. No mechanic!

Plug and play!

- I repaired our front loading washing machine when it tried to self-destruct. Success is 100% due to internet videos and parts schematics. No repair man!

This one took three hands

- I've repaired our aging irrigation system countless times. It keeps finding new place to fail. I plan to replace all the tubing at some point. No repair man!

- Recently, I rewired a lamp rather than chuck it. It's a cheap lamp, probably worth about $20 but we like it and didn't want to add it to a landfill. No landfill / No replacement!

- The pool vacuum spends it's life underwater in a chemically charged environment. Of course stuff breaks and wears out. I rebuilt this $300+ piece of plastic wizardry with parts and instructions from the internet. No repair shop!

- Speaking of the pool, I again reached out to the internet for parts and instructions to repair our aging DE filter in "You will go to the Dagobah System"No Service Technician! I did later hire a company to replace and upgrade the whole system.

I've had plenty of other fix-it successes like an XBox controller, a vacuum cleaner, a clock, countless toys, some light car repairs, and general household plumbing and electrical repairs. Other stuff, I've had to chuck in the trash when it's simply outside its useful life or just not worth the major surgery to attempt a repair, like televisions, a pool motor, a toaster, and etc.

The Contest!

How about you?

What have you done to save the family budget and keep stuff from the landfill? What's the one thing you're most glad you fixed rather than throwing away? What fix-it job are you most proud of? What do you wish people would stop throwing out and start fixing?

Share your story in the comments below, email it to me ( john@azdiyguy.com), or even send it to me through a Facebook message. A few sentences is fine! Send photos if you like. I'll feature the winner in a future post.

The winner gets a $100 Amazon gift card from Crucial Vacuum ! I'd be honored if you'd follow me on Facebook ! I slip plenty more good DIY content and humor in over there. (Don't forget Twitter, Google+, Hometalk, and Pinterest too!) Have fun!

This contest is complete. We have a Winner

Thank you everyone!

From Crucial Vacuum:

"Crucial Vacuum supply vacuum cleaner parts and supplies, so we're always interested in ways we can encourage more people to fix appliances rather than throw them away. It's great to find bloggers like John, who get more people repairing, recycling, and taking care of things, so we thought it might be fun to see what his readers have been fixing!"

I've looked over their website and loved the how-to videos for installing replacement vacuum parts. I really like the fact that they plant a tree for every 1,000 filters they sell. I also like the price match guarantee, free shipping, and free returns.

Crucial Vacuum is currently running a special coupon code for 20% off a $40 order though March 2014 (Coupon code: POLARVORTEX)

Read the ole' fine print below before entry:

- Relationship: AZ DIY Guy's Projects (Host) has no financial relationship with Crucial Vacuum (Sponsor) and has received no compensation for hosting. They originated the idea for this contest, thinking my readers would enjoy it and would appreciate their products and services. I'm hosting this contest as a way to engage and reward my awesome readers as well as meet new ones. Amazon, Facebook, and other third party social media outlets are not affiliated with the contest.

- Duration: The contest runs through March 26, 2014 at 11:59 pm, Phoenix, AZ time.

- Location: The contest is open to the US and Canada only. Participation is void if any a participant's local authority having jurisdiction deems this contest to be illegal in any way. Participants are responsible for verifying their legal eligibility.

- Eligibility: Only individuals over 18 are eligible, no company or organization. Bloggers are welcome. Employees and family members of AZ DIY Guy's Projects and Crucial Vacuum are ineligible. Entries or comments that are deemed profane, hateful, discriminatory, or otherwise distasteful will be removed and are not eligible.

- Entry: Participants enter the contest via a written commentary / story. Entries are accepted via: 1.) comments on this original blog post 2.) Facebook message to the AZ DIY Guy page 3.) Email to john@azdiyguy.com

- Winner: The winner will be chosen editorially and subjectively at the discretion of the host and sponsor. Following or subscribing to the host or sponsor of the contest on social media is not required for entry (although it is greatly appreciated!). Photographs are not required, but would be great to post on the winning announcement.

- Notification: A good-faith attempt to contact the winner will be made via the contact information provided at time of entry. The winner has 48 hours to respond, before forfeiting and an alternate winner is chosen.

- Prize: The sponsor is responsible for providing the prize, a $100 Amazon.com gift certificate to the winner. This certificate may be digital or physical at the discretion of Crucial Vacuum.

- Release: Participants allow their story, comments, and identity (as supplied) to be shared.

- Errors: The host and sponsor are not responsible for any potential, technical errors into the contest. An best effort will be made to resolve any errors fairly. If a legal error is discovered, adjustment to the contest will me made to ensure compliance or the contest can be cancelled.

- Acceptance: By entering the contest, participants accept the terms and agrees to hold the the host, sponsor and any social media used harmless in the event of an error or omission.

- Spam: Spam will be deleted. Seriously. Shame on you.

Want to win that $100 certificate?!! Let's hear your story!

This contest is complete. We have a Winner

Thank you everyone!

Actually reading instructions and other nonsense.

Although I leap unhesitatingly into all things DIY, and am generally fearless to tear stuff apart and (try to) fix it, I've never claimed to be an auto mechanic. It's just not my expertise. I think it comes from growing up in Michigan where everyone else's dad but mine worked in some way for the auto companies. I had so many car-handy friends that they'd just help me with it, no problem. I never really learned much about it.

However, I have changed headlamps before, and I am a handy guy. After all, I kicked butt fixing the auxiliary audio jack in my truck, didn't I? When I popped outside to fix Sweetie's car, I took a cursory glance at the owner's manual to see how to remove a plastic air duct that was in the way, without breaking the plastic clips, before swaggering to the front of the car to fix the hell out of it, 'cause I'm a handy, handy man.

|

| Yep! Shorts in February!!! |

|

| The 2007 Honda Accord Ladies and Gentlemen. |

|

| Precisely different sized lamp bases, exactly and positively wrong. |

|

| "I'm with stupid à" |

DIY Lamp Repair - A Fixing Stuff Adventure

|

| This floral shade is way to pretty for my workshop. |

|

| Removing the set screw. |

|

| A little of the old push 'n pull technique |

|

| Like Ruffles, it has ridges. |

|

| Yes, it's "green apple" scent. |

Note to self: future project - find a shapely, plastic woman's leg and make my own, fragile Christmas Story lamp to display in our front window. The wife will love it!

|

| Believe it or not, I've never had a manicure my whole life. Honest! |

After that, it was just a matter of reassembling everything I had taken apart, in reverse order. It's probably best to lay the pieces in order on your workbench rather than fling them randomly about like I did, resulting in a pissed-off Easter egg hunt. I fed the cable backwards through all the elbows until there was just enough to fit into the socket enclosure. All the various nipples threaded back in with their retaining nuts tightened.

I gently threaded the lamp in. Finally, the moment of truth, my friends.. (click)

|

| Blinded by the light, revved up like a deuce, another runner in the night!! - Manfred Mann's Earth Band |

There's nothing better than a nice book under the warm glow of a reading lamp...

The Great Debate: Hiring a Pro vs DIY (Replacing Swimming Pool Equipment Edition)

- A new cartridge filter to replace the aging DE filter (the big R2-D2 looking thing) so back-washing and dealing with that messy white powder is a thing of the past. Old leaky here has been a maintenance nightmare. It would need hundreds of dollars in replacement parts if we wanted to save it. A cartridge filter will reduce my maintenance time greatly.

- Replace the pool pump. The existing motor is doing fine, since the it was replaced a year ago (home warranty!!!) but, we expect to save about $700 annually in power consumption by upgrading to a modern, variable speed pump. Plus, the unit is tired and has air and water leaks.

- Adding a salt water cell. This is actually exciting. We are going to nearly eliminate our chemical dependency (and cost!!!!) by converting salt water to chlorine. Everyone I talk to who's made this conversion has loved it.

|

| No swamp. |

|

| Swamp. |

Homework: There's a neat article Marcie Geffner wrote last year for Bankrate.com, titled Remodeling Yeilds Rewards, Vexations where she compares my successful family room remodel experience to cautionary advice from the authors of Home Improvement For Dummies. I do their cautionary, contrasting point of view vs. my gung-ho, I-can-do-anything approach. Doing research, I found their website diyornot.com, which provides lots of info on DIY vs. hire. It's a very good site. I just get a vibe that it's pushing the hire direction a bit hard, especially with an apparent choice of advertisers directed towards for hiring contractors. Maybe I'm a bit sensitive because I love the do it yourself approach. Heck, I have ads for tools and materials on my site. - John

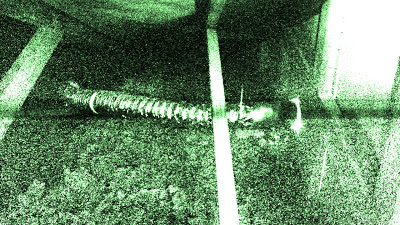

A Relaxing Labor Day Project: Underground Electrical

Even though I'd proclaimed it a no-project weekend, I started excavating the slab the equipment is sitting on. I thought I'd be nice and hopefully avoid the cost creep of having a pool tech digging at $80 / hour before dropping down a new slab. I dug it out pretty quickly.

|

| One of the many leaks dribbling away. |

Of course, it wouldn't be a ripping good DIY Guy project experience if it ended as neatly as that, would it? Nope. Remember Murphy's Law, my friends. I noticed this little gem of awesomeness:

|

| "Don't you call me a mindless philosopher, you overweight glob of grease!" |

conduit, wrapped in corrosion preventing rubber tape. Awesome. Guess what else?!!! There's cement covering it too. Oh, joyous day!! But that's not all; there's a thunderstorm bearing down on me. Sweeeeeeeeeeeet, now this is a holiday, my friends!!! So much for BBQ, it's going to be a carryout pizza night.

|

| The conduit on the left and the gounding box on top are brass, and in perfect condition. |

|

| Can you tell the new from the old? |

|

| 100 degrees and humid after the storm. It's not quite as fun as it sounds. |

I put all the wiring back exactly the way it was before. I recommend you don't mess around with electrical near a pool if you're not really comfortable with it. Seriously, hire an electrician. There's a whole section of code devoted to it.

|

| Generally, you don't see pools this color outside St Patrick's Day |

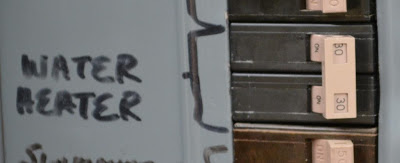

Installing a water heater shut-off switch

Last time, I mentioned I couldn't quite get to a water heater maintenance program without doing some repairs first. I figure step number one is to bring the electrical up to snuff. I decided to install a disconnect switch by the unit, so I don't have to trudge to the outdoor electrical panel every time I want to shut the unit off.

Before I could get going on this part, I had to replace the breaker. My predecessors had installed two, single pole breakers, rather than one double-pole 30 amp breaker. Not cool my friends.

AZ DIY Guy's Scary Warning - Electrical Edition: Don't mess with electrical, unless you know what you are doing. 120 volts of household current can kill you just as dead as much higher voltages, it just lets you suffer longer, and folks can still recognize you in your casket. Plus, electrical issues can do a heck of a job burning your house right to the ground. When in doubt, get a professional electrician. If you do the This project is a snap for someone who's trained; it shouldn't cost too much. Even if you know what you are doing, I recommend you work it like it's live, even if it's not. Research legal requirements in your area before making changes to your electrical system. Finally, don't take my word for this stuff, I might be some random idiot on the internet.

No. Not cool at all. Those are separate breakers. I picked up a breaker at Home Depot for about 13 bucks. It was an easy swap; just a matter of turning off the main breaker for a minute while I slipped the two originals, popped the new one in, and re landed the wires.

Of course it couldn't go perfectly. I noticed, for the first time that this particular circuit's wiring was aluminum. I hate that I have aluminum wiring. More on that later.

Cool. Very cool indeed.

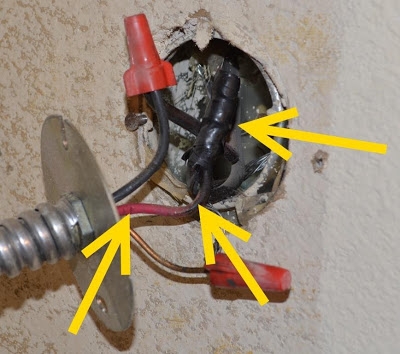

I turned off the new 2 pole circuit breaker and moved inside to open up the junction box to find,... a gob of black electrical tape, discolored wire, and nicked insulation (clockwise below). Not good signs.

Since I don't trust ANYTHING in this place, I like to do a quick check to see if the circuit is still live. Especially if there's some sketchy-looking wiring where I'm about to stick my fingers. Idiots could have easily landed one of the hot wires to the wrong breaker; it could light me up. No thanks. It's time to reach the Bat Belt for my trusty non-contact voltage tester.

.

.

Apparently, It's pretty serious.

Ahhhhh,... sweet silence. The circuit is dead.

This is scary. The wire nut inside the tape glob is completely destroyed. Worse yet, where is the rest of it? There were no fragments or pieces of more than half of it, not in the tape, not in the junction box. To me, this means some mental giant actually knew this was busted and wrapped it in electrical tape, rather than simply installing a new wire nut. This could burn a house down to save the effort of installing a cheap wire nut. Jackassery! I think it's especially unsafe in that it's aluminum to copper wire junction.

That's an identical, complete wire nut on the right.

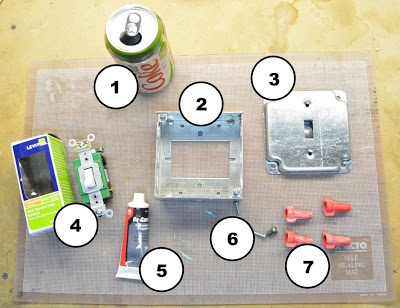

Back over to the workbench, I set up to prefabricate the switch assembly. Here's the stuff:

Diet Coke Lime The lime is important. I can't find the reference exactly, but it's in the National Electrical code somewhere,...promise.

Square Box Extension Ring. This will extend the in-wall box allowing for more room to fit the switch and wiring.

30 Amp, 2 pole switch I chose Leviton's extra heavy-duty spec-grade.

Anti-Oxidant CompoundThis gunk is required when you tie copper to aluminum wiring.

Screws: 8/32's to screw the window box, and one ground screw to ground it. (... to rule them all!)

Wire Nuts ..you know,...to nut wire.

I clipped the ears off the switch, so it would fit nicely behind the plate.

I pulled the existing 6/32 mounting screws out of the switch, since they're not needed here. Next, I stripped some new #10 copper wire and installed it behind all 4 termination screws, the line side (the "home run" to the breaker) on the black screws, load side (to the heater) on the brass.

No, the WD-40 and the big ol' bottle of blowin' bubbles are not necessary.

I like to put a wrap of electrical tape around the device, leaving a folded, courtesy tab for easy removal later.

Pop the cover on with the two short 6/32's (included with the cover) and we're ready to install.

The extension ring installs on the wall, screwed to the back box in the wall.

The stripped, bare copper and aluminum wires got a good bit of the anti-oxidization goop. Man! I wish we didn't have that aluminum wiring. At least it's only on a few circuits in the house.

All wired up and sealed in place. I slipped on a 90 degree flex connector, pulled fresh new wire to the heater, terminated it, and sealed everything up.

Flip the breaker and power it up. We should be in business, just in time for the next laundry cycle. Now I can shut the whole thing off whenever I'm finally able to drain it for maintenance.

Look good?

To check the voltage, I popped off the front cover, peeled out a piece of insulation, and exposed the internal wiring terminations for the the heating element. Careful, careful,.. 120 volts from both of the hot conductors to ground and 240 between them. Done!

240,...243.7, whatever it takes.

Next time kiddies, it's on to plumbing. I have to repair or replace that corroded, seized shut-off valve. I'll have to do some research on that one.

Before servicing the water heater...

I found that water heaters should be drained and flushed as much as twice a year?!!! and the sacrificial anode rod

What a great opportunity for a blog post on water heater servicing right? Drain it and check the rod, piece of cake. Let's do it this weekend kiddies!!!

Nope. Because of this stuff I need to deal with first.

A) within sight,... or

B) capable of being locked in the open position (power off) position.Our electrical panel is outside, as is common here in Arizona. Technically, we may be ok, since the breaker can be locked out (if I buy a lockout kit). It's fuzzy, the locking means is supposed to be there even if it's not locked. Either way, I don't like it. Electrical code is minimum. I want better in my own home, so I'm going to install a switch.

Just to spice things up a bit, I just found another little Inheritance from my DIY Predecessors. Instead of the 2 pole, 30 amp breaker, they installed two 1 pole 30 amp breakers. Not cool, IMHO. The two pair in the yellow circle should look like the three in the blue below. It's not safe to turn off or trip half a 240 volt circuit, both should turn off together.

|

| Alas, this fine, Shakespearean penmanship is not mine to claim. |

|

| Crust is good on apple pie, not on plumbing. - AZ DIY Guy |

I suppose I'll start with the electrical. Hopefully, I don't discover anything else shocking. Check in next time as I head towards eventually getting on a regular maintenance program.

PS - Do I at least get points for making it through the whole post without calling it a Hot water heater?

Moving through another door

This time it was Jack's bedroom that got completed. His door had sat, half-painted for four months or so, while I tackled other pressing projects (see the index, April through July). I do get off-track.

I pulled his (young) man-cave door, complete with HAZ-MAT warning and an electrician's lockout tag-out tag out off it's hinges.

I've also started monkeying with the new DSLR camera and tripod, so "action shots" of yours truly are possible. Although, seeing my mug isn't much of an improvement, I can finally show some better photos than the ol' camera phone, and share some updates to my methods.

|

| Cooooooooookies!!! |

|

| Yes,.... that's the mighty, still not finished, organizer project under there. I'm not proud. |

Step 1: Slop some glue on toothpicks. Make sure to open the box in such a way that you spill them all over the floor as I have, otherwise the technique won't work. If you're wearing nice clothes to work in (ahem, Jeff), a damp paper towel is nice to have on hand.

Step 2: Jam a three or so gluey 'picks in the hole and savagely snap them off. There's no need for ceremony here. We're cleaning up after barbarians. Note: The spattered glue on my hands is a controlled exercise, just an educational illustration of one possible outcome, if you get overzealous in the glue application. It would never happen to me in real life. I'm sacrificing for you, dear reader.

Step 3: Run the screws in. Pro tip: I like to turn my screws in clockwise, otherwise known in the scientific circles as "righty-tighty". Do it your own direction, I'm just sharing what works for me. Again, I used the insulated #2 Phillips tip screwdriverbecause, well.... I don't know.

"You will go to the Dagobah system"

Luke Skywalker: [weakly] Ben?

Kenobi: You will go to the Dagobah system.

Skywalker: The Dagobah system?

Kenobi: There you will learn from Yoda, the Jedi Master who instructed me.

- Star Wars, Episode V, The Empire Strikes Back

You know how some things sound really great, but when you take the plunge, not so much? I'm talking about convertibles, pet boa constrictors, joining the French Foreign Legion, and, of course, swimming pools. Visions of sparkling summer recreation can quickly turn into the reality of a green, swampy pit of wallet-sucking, time-stealing forced labor for survival misery. The planet Dagobah.

BUT, access to a swimming pool, in Phoenix, is pretty much compulsory. It's like having a snowmobile in Northern Michigan. It's mid-June, and I still haven't gotten our pool operational. The weather would have allowed for swimming in April, but it's been a constant battle with the pool to get it habitable. It's an old pool, in need of a serous top to bottom retrofit, but it's cool, wet, and does the job, usually.

|

| At least someone is swimming. |

I'd already torn the filter apart and cleaned it twice this year. This time, it was blowing D.E. (diatamatious earth) filter-aid powder back into the pool. In the morning, it was easy to see that yellow slime mold was taking root again. Basically, the filter cycling dirty muck right back into the pool.

|

| Even our house guest, Bella thinks it's horrid |

takes 8 screens that look like fish skeletons covered with sail canvas. Locally, they cost 30 - 40 bucks (EACH!!!). I try not to replace them unless I absolutely have to, one at a time. Since Sweetie and the kids are bugging me and summer in the desert is in full (heat of hell-fire) blast, I bit the bullet and ordered a full set. Luckily, Amazon had a full replacement grid set

|

| Remember the way to kill a zombie? |

|

| Good night, sweet desert oasis |

|

| Bella approves, but the Barracuda lurking below makes her nervous |

Fixing it up, again

At some point in the ongoing adventures of home ownership and remodeling projects, I think everyone finds themselves at the point where they are re-remodeling or fixing stuff they were already proud to have called finished.

At some point in the ongoing adventures of home ownership and remodeling projects, I think everyone finds themselves at the point where they are re-remodeling or fixing stuff they were already proud to have called finished.Upon study, it's my hypothesis that this natural phenomenon, normally brought on my age or changing tastes, is greatly accelerated by the presence (infestation) of the pint-sized interlopers commonly referred to as "children".

|

| I think a cannon exploded right about here. |

|

| Ohhhhhh,..... the horror! |

|

| Sand-tastick |

Installing new facia boards,... solo style

|

Loading the big 16 footers into a pickup with a 5 foot bed was a challenge. Even shoving them through the sliding rear window left too much hanging out the back, so I opted to go upstairs with it:

|

| Not a surfboard, dudes. |

|

| Clampeyness |

|

| Scribing the outside angle. |

|

| B.A.M.S having lunch. |

|

| Bang - Bang - Bang |

|

| Mr. Hook, it's been lovely, but you'll not hold Christmas lights again. |

|

| It's a Stubble Sunday, but you just can't take your eyes off the ol' chapeau can you? Don't be jealous. |

|

| Ye old nail slicer. |

Replacing our bathroom exhaust fan

A trip to the home center for a replacement found me staring slack-jawed at a huge display of ceiling-suck-age options, ranging from $30 to $200.

Uhhhhh,... I came prepared complete with the info of: about 12" x 12" square. I was certainly not prepared with CFM measurments, Sone ratings or, most importantly, funds up to $199.99. Since the slack-jawed, staring approach didn't seem to resolve much after a few minutes, I did some split-second Matrix style education,... I looked it up on the smartphone. I find that the deal on CFM ratings is that it's the speed / amount of air the fan moves, in cubic feet per minute. I found a formula and plugged in our measurements:

- (1 ) box of Band-Aids (Angry Birds)

- (3) tape measures

- (1) Diet Coke

- (1) Photo of Kirby (our dog who passed in 2010)

- (1) Doggy Valentine's card

- (1) Hand drawn "note" with hearts and "Daddy"

- (4 ) Pretty rocks

- (1) Small bag of 1/2" nuts and bolts

- (7) 3" finishing nails

- (1) Extra dust mask

|

| I could see the target in my high-beams. |

|

| Daddy's helper. Thanks for the Coke sweetie! |

|

| Clamp, plug & play! |

|

| Duct,..duct,... duct,... GOOSE! |

|

| Classified: Just between us right? |

|

| Note a very important detail in this step: no bald spot. |

|

| Thar she blows! |

UPDATE!! I'm honored to have this story chosen to be featured an Bob Vila's website as part of the "Bob Vila Nation" of contributors from the blogging community. Please check it out and give me a vote by the hammer image, if you like the story.

UPDATE!! I'm honored to have this story chosen to be featured an Bob Vila's website as part of the "Bob Vila Nation" of contributors from the blogging community. Please check it out and give me a vote by the hammer image, if you like the story.The best laid plans...

Then BAM! The washing-machine self destructs. Gotta drop everything and fix it. Tear down and rebuild.

|

| Frickin' frackin' rubble bumbin' mumble mud... |

...then, BAM! The awesome Baracuda Zodiac G3

... then, BAM! The guest bath exhaust fan gives it's death rattle. Inside, it's an unholy fossilized mess of rusted metal. Carbon-dating analysis puts it's installation in the long bygone era of 1979. I think the only thing holding it together is the rust.

|

| This weekend's recreational activity. |

An Emergency Washer Repair Challenge

Our LG front loading washing machine tried to self destruct! Here’s how I fixed it myself and saved a ton of money

Read MoreThe front door. Someone actually did this to their own home,... on purpose!

Undesired Inheritance from our DIY Predecessors

Remodeling a house and finding the half-assery left by previous, drunken DIY'ers.

Read MoreInstalling the New Pocket Door

I'm installing the new pocket door for the master bath today. I'd already prepared our new six-panel door, trimmed it to fit, primed the fresh edges, and painted the whole thing with a couple coats of white, semi-gloss last weekend. If you missed the story, find it here; it's a cliffhanger. The last coat of paint went on 6 days ago, so it's nice and dry, out in the workshop.

I'm installing the new pocket door for the master bath today. I'd already prepared our new six-panel door, trimmed it to fit, primed the fresh edges, and painted the whole thing with a couple coats of white, semi-gloss last weekend. If you missed the story, find it here; it's a cliffhanger. The last coat of paint went on 6 days ago, so it's nice and dry, out in the workshop.The dang thing keeps falling off its rail, plus it rubs on the inner walls of the pocket as it sways loosely from the track. I've already replaced the track mounting screws with larger screws, they seem to be holding. Look how ugly that beat up old slab door looks!

I pulled the top two trim pieces (casing?) off to access the mounting hardware, showering the whole area with bits of drywall from the rough edge behind. It isn't the best looking installation of trim I'd seen, with heavy globs of caulk filling the voids. Maybe when we redo the bathroom, I'll re-trim the whole thing with wide trim.

|

| Child Labor Rocks !!! |

|

| Like most men, I have a one-track mind. |

Turn the brain back on,.. climb back up the step stool,... crank the wheels back up,... climb down the step stool,... swing the door out,... climb back up the step stool,... extend the rollers again,...

|

| What do you think? Better? |

The DIY Guy vs. Dealership Challenge 2013!

|

| You don't know jack! |

|

| Looks like a snap. |

Holding the part in my hand, it looks like a snap in deal with a plug-in wiring harness in the back. Fairly easy, for $84 in labor? Can I get to it behind the dash. Any of those pesky clips you can't figure out and end up breaking hidden in there. Still, I'm pretty sure I can beat it. Thus,...

|

| On your mark, get set... |

- A trained, professional automotive mechanic, wearing dark-blue coveralls (coveralls assumed)

- A full set of specialty automotive tools

- Experience with this procedure, in this vehicle

- A heated work space (it's 35 degrees in my driveway)

- Manufacturer's reference material

- Smug, professional confidence

- free coffee in the waiting room

- My lucky Dunedin, New Zeland ball cap (a gift)

- (2) mugs of Kirkland Signature, Pacific Bold, Dark Roast Coffee, Extra Bold coursing through my system

|

| Pop out these thing-a-ma-jigs. |

Nothing broken! I got one of those early bursts of confidence, you get when nothing goes wrong early in a project. Dangerous.

Nothing broken! I got one of those early bursts of confidence, you get when nothing goes wrong early in a project. Dangerous.  I gently pulled the jack forward and fed a little of the slack cable through the opening. There was enough to twist and rotate the assembly so I could get a good eyeball on it. There wasn't even a clip on the little green plug for me to break! I grabbed the plug and the jack assembly and slowly pulled / wiggled it apart. Bingo! No problems so far. The plug popped into the new jack and the jack snapped into the dash. I clipped the plunger / piston onto the glove box, reinstalled the two bumper things, removed them both when I realized I needed to semi-close the box first, reinstalled them again, and, using the most difficult technique of the day, flipped the box closed. That was easy, too easy, waaaaay too easy...

I gently pulled the jack forward and fed a little of the slack cable through the opening. There was enough to twist and rotate the assembly so I could get a good eyeball on it. There wasn't even a clip on the little green plug for me to break! I grabbed the plug and the jack assembly and slowly pulled / wiggled it apart. Bingo! No problems so far. The plug popped into the new jack and the jack snapped into the dash. I clipped the plunger / piston onto the glove box, reinstalled the two bumper things, removed them both when I realized I needed to semi-close the box first, reinstalled them again, and, using the most difficult technique of the day, flipped the box closed. That was easy, too easy, waaaaay too easy... |

| Get up, Everybody's gonna move their feet, Get down Everybody's gonna leave their seat You gotta lose your mind in Detroit Rock City |