Both of our bathroom exhaust fans are shot. The one in our guest bath was a beast at one time; it sounded like an F-16 afterburner on takeoff and moved air like a pissed-off hurricane. I'm surprised it didn't pull the door off its hinges. Certainly, it blew too much of our costly air conditioning up into the attic. Now it's fried.

A trip to the home center for a replacement found me staring slack-jawed at a huge display of ceiling-suck-age options, ranging from $30 to $200.

Uhhhhh,... I came prepared complete with the info of: about 12" x 12" square. I was certainly not prepared with CFM measurments, Sone ratings or, most importantly, funds up to $199.99. Since the slack-jawed, staring approach didn't seem to resolve much after a few minutes, I did some split-second Matrix style education,... I looked it up on the smartphone. I find that the deal on CFM ratings is that it's the speed / amount of air the fan moves, in cubic feet per minute. I found a formula and plugged in our measurements:

Now that it's all done, I guess I should have tested the fan to make sure this one wasn't a dud. Luckily, it worked just fine. I actually had to strain to hear it. I almost miss the clattering din of the old one.

UPDATE!! I'm honored to have this story chosen to be featured an Bob Vila's website as part of the "Bob Vila Nation" of contributors from the blogging community. Please check it out and give me a vote by the hammer image, if you like the story.

UPDATE!! I'm honored to have this story chosen to be featured an Bob Vila's website as part of the "Bob Vila Nation" of contributors from the blogging community. Please check it out and give me a vote by the hammer image, if you like the story.

A trip to the home center for a replacement found me staring slack-jawed at a huge display of ceiling-suck-age options, ranging from $30 to $200.

Uhhhhh,... I came prepared complete with the info of: about 12" x 12" square. I was certainly not prepared with CFM measurments, Sone ratings or, most importantly, funds up to $199.99. Since the slack-jawed, staring approach didn't seem to resolve much after a few minutes, I did some split-second Matrix style education,... I looked it up on the smartphone. I find that the deal on CFM ratings is that it's the speed / amount of air the fan moves, in cubic feet per minute. I found a formula and plugged in our measurements:

Cubic Feet = Length: 9 ft. x Width: 5 ft. x Height: 8 ft. = 360

360 cu. ft. ÷ 60 minutes per hour = 6

6 x 8 air changes per hour = min 48 CFM fan needed

I bought a Hampton Bay (#986 755), 50 CFM, 0.5 Sone (Ultra Quiet) for $ 48.97. It turns out the old one was rated for 180 CFM and screamed its furious banshee wail at 5.0 Sones. Folks with bigger bathrooms will need bigger fans, and deeper wallets.

Back at home, I tried to pull the cover and found that this one was held in by rusted screws, not the handy springs I'd seen more recently on our other fan. Up close, this cover is a yellowed, paint spattered mess. I cut the paint and caulk from the edge with a utility knife before I pulled it down.

Next, I geared up for the dreaded attic crawl. Our attic is a filthy, itchy mess of ancient, blown-in insulation horror. It's never fun. I loaded a tool bag with all the tools and material I might need. When I returned from changing into long pants, a long sleeve shirt, and a spare t-shirt wrapped around my head and tucked into the back at my neck, I found my tool bag had been substantially supplemented.

Gracie was worried about me going into the attic, without her. She'd helpfully loaded up my tool bag with:

- (1 ) box of Band-Aids (Angry Birds)

- (3) tape measures

- (1) Diet Coke

- (1) Photo of Kirby (our dog who passed in 2010)

- (1) Doggy Valentine's card

- (1) Hand drawn "note" with hearts and "Daddy"

- (4 ) Pretty rocks

- (1) Small bag of 1/2" nuts and bolts

- (7) 3" finishing nails

- (1) Extra dust mask

Of course, I had to lug the extra stuff up there, just in case.

I traversed the attic, which ended in a miserable, belly-crawl across the rafters. It was 86º degrees outside in Phoenix; in the attic, it was damn hot. In the light of my headlamp, the fan appeared, it was unfastened and completely without a duct. From what I know, venting your moist shower air directly into your attic is commonly referred to as extremely stupid. It's not going to freeze in Phoenix, but it could cause mold issues and who knows what else. I didn't see any evidence of problems, but it was a dark, hot mess, and I wasn't going to loiter.

|

| I could see the target in my high-beams. |

I lifted the old fan out of the way. Luckily, there was enough slack in the electrical line to push the unit back to where I could at least crouch to work on it. With the hole open, there was a sudden burst of excited chatter from the bathroom below. I couldn't get close enough to the hole to look down. I held my camera phone over the edge to take a blurry recon shot:

|

| Daddy's helper. Thanks for the Coke sweetie! |

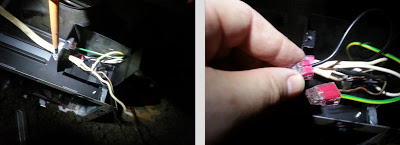

With the power off, I opened the wiring compartment and took the wires out of the wire nuts. I slid the existing, three wire cable into the compartment of the new fan and clamped it down, using the connector (NM 3/8-Inch Clamp Type Connector ) I had installed earlier, in the comfort of the garage. This particular unit used the push-in style quick connectors for the wiring. Normally, I cut them off and make a tight, twisted joint with my Linesman Pliers

) I had installed earlier, in the comfort of the garage. This particular unit used the push-in style quick connectors for the wiring. Normally, I cut them off and make a tight, twisted joint with my Linesman Pliers and wire nuts, but in the dark, hot attic, I was pleased to go with the plug-and-play approach.

and wire nuts, but in the dark, hot attic, I was pleased to go with the plug-and-play approach.

|

| Clamp, plug & play! |

I had bought a wall vent ducting kit as well. The 4" flex duct attached to the fan exhaust port with an included zip-tie. I added a quick wrap of the metallic foil tape that I had left over from the ceiling project. I shoved the new fan back over the hole and screwed the supports to the nearby studs.

as well. The 4" flex duct attached to the fan exhaust port with an included zip-tie. I added a quick wrap of the metallic foil tape that I had left over from the ceiling project. I shoved the new fan back over the hole and screwed the supports to the nearby studs.

|

| Duct,..duct,... duct,... GOOSE! |

QUICK TIP: Ready to run the duct to the outside, and having pulled the bone-headed move of drilling exterior holes into framing members in the past, I took the time to drive a screw through the wall from the inside, so I could find the location easily from the outside, no measuring!

Finding the screw was easy. I shifted to the right to avoid the groove in our "lovely" T-111 siding and traced the 4" hole using the template supplied with the duct kit. Drilling a larger hole near the side of the line with a Spade Bit allowed for saw blade access.

allowed for saw blade access.

Grumbling about the lack of a cordless jigsaw in my collection of power tools, I was forced to the disagreeable task of stringing out an extension cord, like a chump. This Black & Decker Jigsaw is actually the first power tool I ever purchased as a homeowner. It was bought for slicing a countertop to fit a new refrigerator in our first house, probably in 1999. I don't use it a ton, but it's held up very well for a lightweight, economical-grade power tool. Here's their current version, the Black & Decker 4.5 Amp Variable Speed Jigsaw

The duct kit came with a exterior vent with a flap door. An included sheet metal, rigid duct tube snaps into the back and is fed through the wall into the attic. I put a my small torpedo level on a straight line to square it up. Four wood screws zapped in quickly with the impact driver

on a straight line to square it up. Four wood screws zapped in quickly with the impact driver .

.

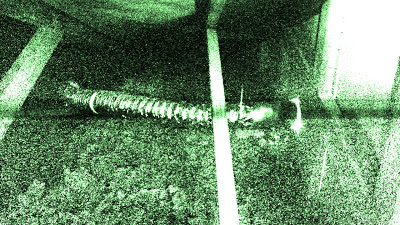

Back in the attic, I attached the flex duct to the rigid duct tube, again with a zip tie and some foil faced, adhesive tape to seal it up. Per instructions, I kept the flex duct in a gentle curve, without making any tight corners. The attic rat mission is an operational success. This highly classified image shows the target has been taken care of:

|

| Classified: Just between us right? |

Returning filthy-clothed to the sweet, air conditioned goodness of inside, I popped the beautiful, new fan cover in place, this time with the easy, snap-in retention springs.

|

| Note a very important detail in this step: no bald spot. |

The exterior vent flap works well. It swings open and closed as needed.

|

| Thar she blows! |

This was a medium difficulty project. Anytime attic work is required, it's a bit difficult and unpleasant, but you can do it. Keep your feet on solid framing and watch out for nails and open electrical connections.

It's not an exciting project to have done; we had a fan and we have a fan again. Just an unforeseen, necessary repair, not a desired improvement project. At least it's quiet and looks much better than the dated, ugly one. Plus, we now have exterior venting.

Thoughts? Comments? I'd love to hear from you.

____________________________________________________

UPDATE!! I'm honored to have this story chosen to be featured an Bob Vila's website as part of the "Bob Vila Nation" of contributors from the blogging community. Please check it out and give me a vote by the hammer image, if you like the story.

UPDATE!! I'm honored to have this story chosen to be featured an Bob Vila's website as part of the "Bob Vila Nation" of contributors from the blogging community. Please check it out and give me a vote by the hammer image, if you like the story.