Hideousness Before

I haven't worked on the Living room remodel for a looooong time now. It's been stalled. Eleven months after starting, I received a big kick in the butt to finish the project. A challenge issued by BLACK+DECKER has inspired me to return to the room with an arsenal of tools and materials to kill off the last pesky bit of this project.

Stick with me friends, I'm going to share how to win a pile of sweet BLACK+DECKER power tools or $10,000 at the end of this post!

If you've been with me from the beginning, remember the stained, wrinkled carpet, moss-green walls, cheap TV stand, and misfit slip covered couch in this 1979 builder-basic room? Here's a quick tour of the heroic burst of action that started this project, before I burned out on it:

It was a lot of work. New paint, bamboo flooring, base molding. crown molding, and a shelving unit changed the room dramatically. Then I ran out of steam. The project was stalled but the calendar marched along.

Now with a swift kick to the posterior by BLACK+DECKER , it's time to finish.

Challenge accepted!

- Barney Stinson

So, what's left to wrap this project up? This, opening,.. archway,.. doorway,... door-hole thing between the living room and dining room / kitchen area.

This opening features beat-up, rounded corners. This style of rounded corners is popular here in the southwest, in newer homes. This is the only location in our home that has them, probably a 1979 premium-upgrade from the tract home builder.

ughhhhh.

They don't fit the style of the house and are in rough shape. The crown molding above it is still unpainted. The base molding is incomplete.

THIS , is where I make my stand.

THIS is where I WILL FINISH A PROJECT!

Go time.

The rounded corners were not exactly going away, they were going to get buried, encased behind a more appropriate finish for our house. I'd found a melamine-coated, MDF window casing board that would fit perfectly, It was very affordable compared to normal lumber and would save tons of time by skipping routing the edges, priming, and painting. I just had to cut it to fit.

Safety first, my friends. Eyes and ears.

I pre-drilled and screwed in the top piece, placing the screw heads close to the edges where they would be hidden by the vertical pieces.

This BLACK+DECKER drill is like the ones included in the weekly prize packs The last bits of original, low-profile base trim popped off easily with a mini-pry bar.

I don't mean to pry, but... wait, I guess I do mean to pry.

The verticals got shot in place with finishing nails. I tried not to use too many, because I didn't want to overdo it with holes to fill later. That's really difficult for me, because I generally love blasting away with nail guns, like I'm gun-fighting at the O.K. Corral.

Let me level with you; keep this plumb straight.

I scribed a pencil line 3/16 from the edge with a compass. This is where the trim will line up, leaving a decorative edge reveal.

The Humble Compass: Not just for circles anymore, baby!

With a 45 degree miter cut so that the low end of the cut starts at the intersections of my horizontal and vertical scribed lines, the first piece of door trim got shot in place. This time I used the brad nailer to leave smaller holes. I glued the corner pieces and wrapped the whole opening.

"Skadoosh!"

For once, I'd actually thought ahead. I already had cut pieces of the new, beefy base trim months ago when I did the rest of the room. These treasures already had the complex angled cut done. All I had to do was trim them with the miter saw to fit against the new trim molding.

A rare sighting of a Happy-icus Camper-us in his native habitat.

This particular specimen has a large, toaster-shaped head.

After that, it was just a matter of whipping out a tube of caulk and hitting the seams. I used a special color matched type that wouldn't require painting. It was stocked right next to the trim at the home center. I also puttied the nail holes with "Plastic Wood" which left a glossy finish, matching the trim.

Pardon me while I whip this out.

After FINALLY finishing caulking and painting the crown molding, I was DONE! I finally FINALLY finished with this room. Thanks to a shove from BLACK+DECKER, I managed to wrap this room up in slightly less than a year . Yeah, I'm on fire!

We still need to pick up a rug, a comfy chair, a coffee table, and perhaps couple small side tables, but construction is 100% complete.

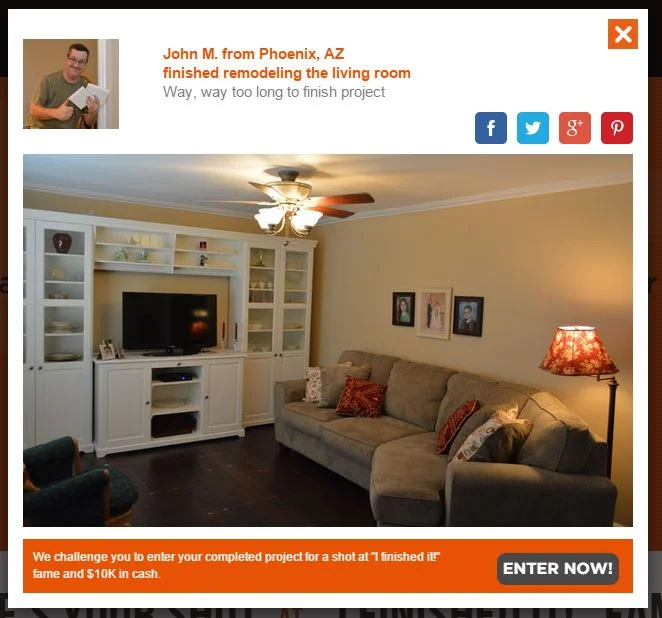

Here's the big finish!

BEFORE

AFTER

BEFORE

AFTER

YOUR TURN!

Update: SORRY Contest Closed

Now it's time for Your Big Finish which could net you some serious cash and prizes. Jump on over to BLACK+DECKER's contest page and share your project, big or small.

BLACK+DECKER has launched a movement to get all the unfinished home projects moving again. Join them for the opportunity to win the grand prize of $10,000 cash! Plus, they might put you and your finished project on a billboard right in the middle of Times Square!

Weekly Prizes are valued at approximately $439.91 per prize and include:

- 20V MAX* Lithium Drill/Driver with AutoSense™ (BDCDE120C)

- Mouse Sander (BDEMS600)

- 4V MAX* Lithium Pivot Screwdriver (BDCS40BI)

- Matrix 20V MAX* Lithium Drill/Driver (BDCDCMT120)

- 20V MAX* Chainsaw (LCS1020)

- Matrix Reciprocating Saw Attachment (BDCMTRS)

- Matrix Impact Driver Attachment (BDCMTI)

Check out the campaign to get inspired by other readers' entries and get inspired to make a project at your house

Update: SORRY Contest Closed

Update: SORRY Contest Closed

Thank you BLACK+DECKER for sponsoring this post and inspiring me to finally, FINALLY finish this project! All work and opinions are 100% my own.